PILING PROBLEMS

& SOLUTIONS

【NOISE&VIBRATION】

1)ENVIRONMENTALLY-FRIENDLY NOISE-LESS & VIBRATION-FREE HYDRAULIC PILE PRESSING/EXTRACTING MACHINE:- Ultimate Solution for Noise & Vibration Problems -

Using the environmentally-freiendly static load hydraulic pile pressing/extracting machine, it is now possible to do the piling job at midnight without causing any problem of noise or vibration.

"Noise & vibration" at job site which conventional piling equipments produced by driving and extracting sheet piles were unavoidable serious problems for many years. Especially if the job site was located in urban or residential areas, "piling noise" gave intolerable discomfort to people living there. If the job site was located close to hospital or school, the piling contractor was very often obliged to stop the job because of excessive "noise." Same was "vibration."

Conventional piling equipments generated a great deal of "vibration" which caused not only the intolerable discomfort but also serious damages to surrounding buildings, roads, railways, etc. Sometimes, the contractor who dared to do the risky piling job close to buildings or historical facilities was sued and obliged to pay a huge amount of money for compensation.

Japan is one of the most advanced countries of "anti-pollution" technologies and regulations. Several groups of Japanese innovative engineers challenged to invent the epoch-making piling machine which could drive and extract sheet piles virtually without noise & vibration. It was the Hydraulic Static Load Pile Pressing/Extracting Machine, which hydraulically pressed in and pulled out the sheet pile virtually without any noise or vibration.

After birth of this revolutionarily environmentally-friendly piling equipments, the Japanese Government strengthened the legal regulations for "noise & vibration" at the construction job site. As a result, all the contractors were obliged to use this kind of piling equipment especially when the job site was located in urban districts and other environmentally-restricted areas. In only several years most of the old-fashioned conventional types of piling equipments were replaced with these new high-tech environmentally-friendly piling equipments. "Noise & vibration" are now the problems of the past in Japan.

This environmentally-friendly, hydraulic pile pressing/extracting machine consists of MAIN BODY, HYDRAULIC POWER UNIT, RADIO & CABLED REMOTE CONTROL UNIT and REACTION STAND. The Main Body contains a heavy-duty hydraulic cylinder which enables the machine to chuck firmly the sheet pile to drive or extract and to grasp with legs the installed piles to hold the machine.

Each sheet pile can be driven or extracted quietly simply pushed in and pulled out virtually without any noise or vibration. This environmentally-friendly pile pressing/extracting machine travels on the piles automatically. It is not necessary to hold the machine by a crane once the machine has been set on the piles. At the start of the piling, the Reaction Stand is used for the base to hold the machine to drive the first three or four piles. Then the machine moves automatically onto the installed piles. This environmentally-friendly

pile pressing/extracting machine can be operated safely by the Radio or

Cabled Remote Control Unit. After the machine has been set up on the

Reaction Stand to start the job or on the installed piles, it requires only a small crane to handle the sheet pile and only three staffs; one machine operator, one assistant to install the pile into the machine and one crane operator.

The machine is so compact and light-weighted. Simple high-tech design.

It’s a piece of "technological art."

For more details, please refer to the pages of "GEOGRAPHICAL DIFFICULTIES & SOLUTIONS" in this web site.

- We can supply used noise-less & vibration-free hydraulic pile pressing/extracting machines at attractive prices. If required, our experienced technical staff will visit you for technical services such as set-up & technical training when the machine is delivered.

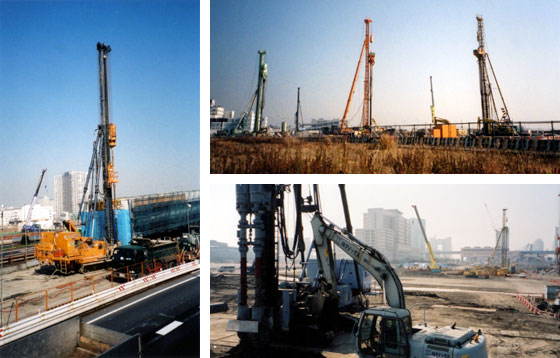

2)MULTI-FUNCTIONAL PILE DRIVING RIGS:

Alternative, versatile solution for noise & vibration problems

Pile Driving Rigs are one of the most popular piling equipments for environmentally-friendly solutions for noise & vibration problems of piling jobs in urban areas, where there is a reasonable working space. Pile Driving Rigs are equipped with the earth auger and the hydraulic hammer or pressing unit. Pile Driving Rigs drill a hole with minimal noise without causing vibration for installation of various types of piles such as PC piles, pipes, H-beams, sheet piles, etc. Pile Driving Rigs are especially suitable for the jobs under tough ground conditions where conventional piling machines are difficult to operate. Environmentally-friendly Pile Driving Rigs can also work for the cement milk injection jobs. Pile Driving Rigs are a versatile, multi-functional piling equipments not only to solve the problems of noise & vibration but also to perform a lot of jobs of different applications most efficiently.

- We can supply used, high-quality Japanese pile driving rigs at attractive prices.

3)HYDRAULIC EARTH AUGER:

3)HYDRAULIC EARTH AUGER:

Hydraulic Earth Auger is another solution. Earth Auger is a machine to dig the ground virtually without vibration and noise. It consists of auger screw and auger head with built-in swivel device. Various types of earth augers are available for specific applications such as piling, pre-boring, excavation, etc. in environmentally restricted areas.

- We can supply used & new Japanese high-tech earth augers.

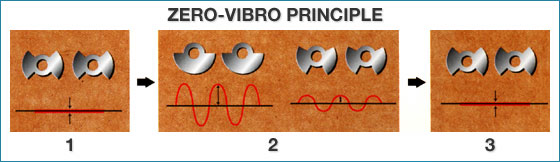

Advanced "environmentally-friendly" technologies have been recently developed for vibratory pile driver/extractors. They are high frequency, eccentric or piston, variable moment vibrators which can comply with the noise & vibration regulations applied for urban piling jobs in Japan. This type of vibrator reduces the driving impact considerably compared to conventional vibro hammers. It generates virtually no vibration to the machine during starting as well as after completion of sheet pile installation ("zero vibration"). Vibration automatically increases only when the pile has been started to be driven under ground, which minimizes the vibration created to surroundings.

- START : Fixed eccentric pendulum and movable eccentric pendulum placed 180 degrees on line of the axis start rotation ( zero start ). Vibro Unit does not vibrate itself until the frequency reaches the specified level.

- OPERATION(MAX) : At the moment when the frequency has exceeded the ground resonance level, the movable eccentric pendulum is automatically converted to generate max vibration amplitude ( illustration – left ). OPERATION(VARIABLE): During operation, eccentric pendulums can be freely adjusted from zero to max at any time ( illustration – right ).

- STOP :Eccentric pendulums return 180 degrees on line of the axis to make the amplitude zero ( zero stop ). The Unit stops quickly without making any resonance with ground or crane boom.

Reference : Catalog of Chowa Kogyo Co., Ltd.